EO Sterilizatoin Service

Ethylene oxide sterilization (EO Sterilization)

The advantage if you choose Omnimate to do the EO sterilization:

We want to offer a streamlined service to all of our customers, you only need to place the order with us, then we can help you to organize all the processes include loading the products into a container. It will save lots of time for the delivery and contact with another supplier.

We will offer a sterilization report for every chamber to our customer, we also cooperate with SGS if our customer needs sterilization validation.

Introduction to ethylene oxide (EO) sterilization

1. It has strong penetrability and can be used for sterilization of various difficult-to-penetrate parts (such as some thinner and longer catheters). It is difficult to achieve sterilization effects by other low-temperature sterilization methods. Only EO or radiation sterilization can be used.

2. It is considered the best chemical sterilant for sterilization and can kill all microorganisms (including bacterial spores). It can be used for sterilization of non-high temperature and humidity resistant items.

3. The damage to the item is small because EO kills microorganisms by using the principle of alkylation instead of the oxidation process, so the damage to the item is very small, and it has a wide range of uses for sterilization of heat-resistant precision instruments.

4. The disinfection method is low in cost and easy to monitor. It is suitable for most medical-grade plastics and requires a longer disinfection cycle to eliminate residues.

5. During sterilization, it can be wrapped with breathable and impermeable bacterial wrapping materials, which is convenient for storage and transportation. Open the package and use it to avoid cross-contamination danger.

Application range of ethylene oxide (EO)

1. Hard and soft endoscopes: arthroscopy, gastroscopy, mediastinoscopy, otoscope, bronchoscope, pharyngoscope, rectoscope, thoracoscopy, colonoscope, prostatectomy device, urethroscope, cystoscope.

2. Medical equipment: anesthesia equipment, hemodialysis, heart-lung machine, artificial kidney, respiratory therapy equipment, artificial kidney.

3. Medical instruments: electric knife pen, dental drill, micro-surgical instrument, electric drill, electric burner, a nerve stimulator, bone drill, needle, artificial joint, pressure gauge, surgical instrument.

4. Cosmetics: finished products, powdered raw materials, bottles, and packaging materials.

5. Plastic products: pacemaker, heart valve, nebulizer, airway intubation, expander, petri dish, syringe.

6. Rubber products: endotracheal tube, dilator, drainage tube, catheter, surgical gloves, sheets

7. Surgical suit

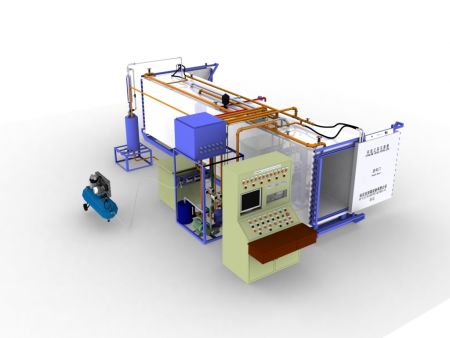

Features of ethylene oxide (EO) sterilizer

1. It can load 13CBM cargo at a time.

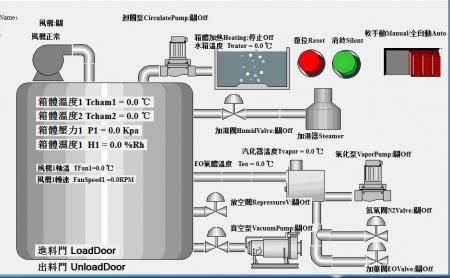

2. Using industrial control computer + SIEMENS PLC control to realize automatic control of the sterilization process, stable and reliable operation.

3. With multiple real-time monitoring devices, improve the type of fault judgment, automatic alarm, and automatic safety protection, safer to use.

4. The sterilizer monitoring and management system can provide multi-level account management, achieve different permissions for different personnel, and have operation record logs.

5. The computer interface and all documents are in Chinese and English.

6. Display and print in the form of reports and trend graphs. The data monitored and recorded during the sterilization process, and the sterilization process parameters are permanently saved.

7. Efficient heating system: It adopts hexahedron hot water circulation heating. It can be designed to be heated in all waters, shorten the heating time, and achieve the best temperature uniformity. It can also add a cooling system to quickly reach the required lower temperature.

8. Efficient pre-vacuum system: Multiple vacuum system options are available: water ring vacuum pump, oil-free rotary vane vacuum pump, Leibo pump + water ring vacuum pump.

>Sterilization Process

1. Load the product into the pot

2. Gas removal

3. Gas fumigation

4. Vacuum drying

5. Finish the pot